- Have any questions?

- +985-727-7400

API Standard 53 Non-compliance Can Get You INC’d

Offshore Technical Compliance Acquires Northwest Technical Solutions

May 1, 2017

OTC Raises the Bar for Compliance Provider with OTC Solutions

May 9, 2017

Though originally issued several years ago, oil and gas operators are now finding that regulatory inspectors are looking for non-compliance with API Standard 53 in their routine inspections – after the standard was incorporated into the regulation in April 2016. Having a plan to prevent a potential incident of non-compliance is the best defense against getting cited. OTC Solutions can help by performing a comprehensive well control gap analysis to show where changes are needed and advise on a corrective course of action.

Issued in 2012, the fourth edition of API Standard 53, Blowout Prevention Equipment Systems for Drilling Wells, was designed to update and strengthen blowout preventer operations with a focus on standardizing operating requirements and prioritizing preventive maintenance, inspections and testing.

“As it often happens with new regulatory compliance requirements, an announcement is made and a stack of guidelines is issued, but too often, companies either fail to make all the necessary changes or are unclear on how the regulations apply to their specific operation,” said Doug Foster, VP of operations at OTC Solutions.

For companies who are either unclear on how API Standard 53 applies to their operation or who just want to be sure they are in compliance, a comprehensive well control gap analysis can be a step in the right direction.

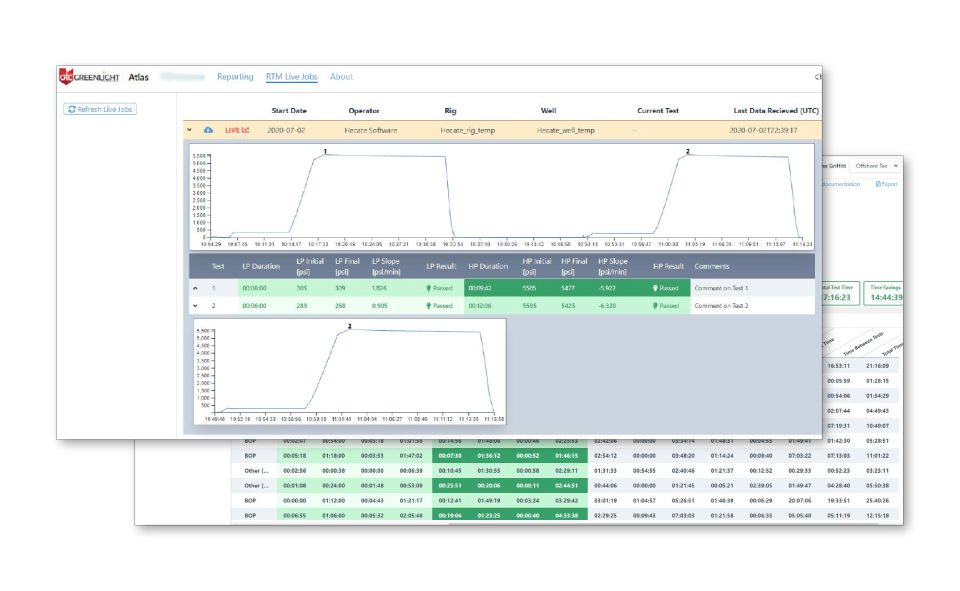

OTC Solutions sends experienced surveyors to the rig to perform a gap analysis of the well control systems. Supported by professional engineers and a team of subject matter experts, the analysis includes an evaluation of compliance to the Code of Federal Regulation – including API Standard 53 and other incorporated API specifications – and is conducted using the Well Control Gap Workscope for subsea and/or surface well control systems.

The inspection process includes the review of the design, maintenance, testing and documentation traceability of the well control system and associated equipment, as well as observing the BOP performing normal drilling operations. Compliance is evaluated by visually verifying equipment, reviewing documentation and working with onsite rig personnel.

Our knowledgeable team looks for potential compliance issues such as:

- BOP closing time requirements

- Testing requirements

- Proper testing procedures and tools

- Accurate documentation requirements

- Up-to-date certificates of compliance for BOP’s

- Equipment standards

- Other related compliance concerns

Once a gap analysis is completed, the OTC Solutions onsite team will review their findings with rig personnel. Additionally, our experienced regulatory compliance personnel prepare a confidential, comprehensive well control gap analysis that is sent to our client detailing our findings and recommendations.

“Our onsite teams are thorough when we are called to a rig to ensure our clients can be confident that they are in compliance,” Foster said. “If we do find issues, we want to provide the company with the specific details of what we found and offer recommendations and guidance on remedying the issues as quickly and efficiently as possible.”

Armed with this level of information and compliance insight, a company can feel confident that they will avoid unnecessary headaches during their next BSEE inspection … or know what action must be taken to ensure compliance.