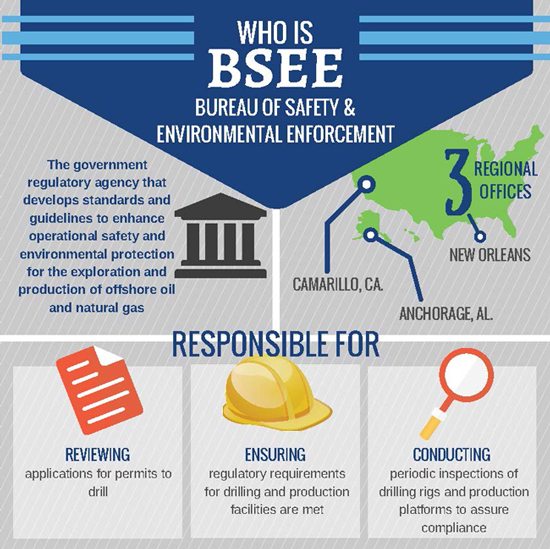

How to prepare for your next drilling BSEE inspection – 09/24/2015

Whether you are anticipating an upcoming annual inspection or have received a periodic unscheduled (unannounced) visit, a little preparation can ensure your operations pass inspection with flying colors.

To help you prepare, Dan Phelps, Senior Inspector and SEMS Consultant, discusses what you can do in order to make your next BSEE inspection go more smoothly.

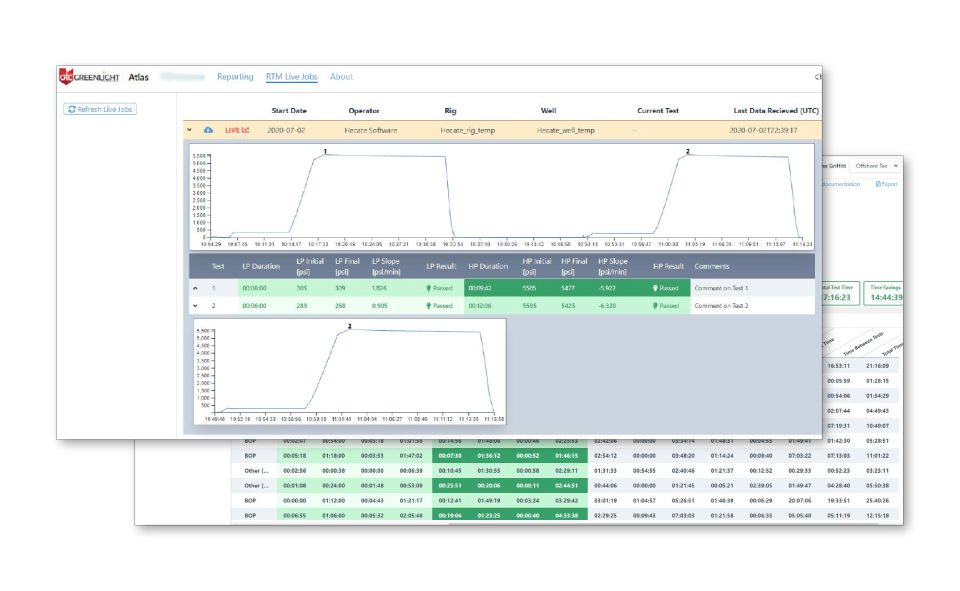

Q: What can operators expect during a BSEE inspection? A: Each inspection is different, but here are the basics— 1. Rig inspections are conducted from the top-down and begin as soon as the rig is in sight. Once onboard, the BSEE inspection team, usually two to four inspectors, meets with rig management to discuss current operations. Afterwards, the inspection team divides into two groups: a documentation review panel and a physical inspection team. 2. The documentation team reviews current and past logs, permits and documents such as drilling and training records, frequency-based testing and BOP test records, IADC reports and accident and injury records. 3. The physical inspection team conducts a thorough walkthrough of the rig looking for elements of noncompliance such as trip hazards, unmarked containers and equipment, marine debris and out-of-date slings. It is also common for the inspection team to conduct informal interviews with rig personnel to see if they are able to communicate their duties and responsibilities in order to determine their familiarity with operating equipment.

Q: What are the different types of BSEE inspections?

A: Inspections can cover a wide range of activities including:

1. Drilling operations including examination of equipment, logs, safety practices, etc.

2. Safety inspections including general procedures, crane lifting operations, pollution and electrical elements.

3. Environmental protection procedures including well completions, well work overs, decommissioning and abandonment and hydrogen sulfide (H2S) exposure.

Q: So what exactly is BSEE looking for during these inspections?

A: Almost every task performed onboard a rig is governed by either company policy or government regulation. It is the job of BSEE inspectors to assure that the rig is adhering to those policies and regulations and that personnel involved in operations are aware of the work environment and the hazards that may be present onboard.

Q: What tools are utilized for BSEE inspections?

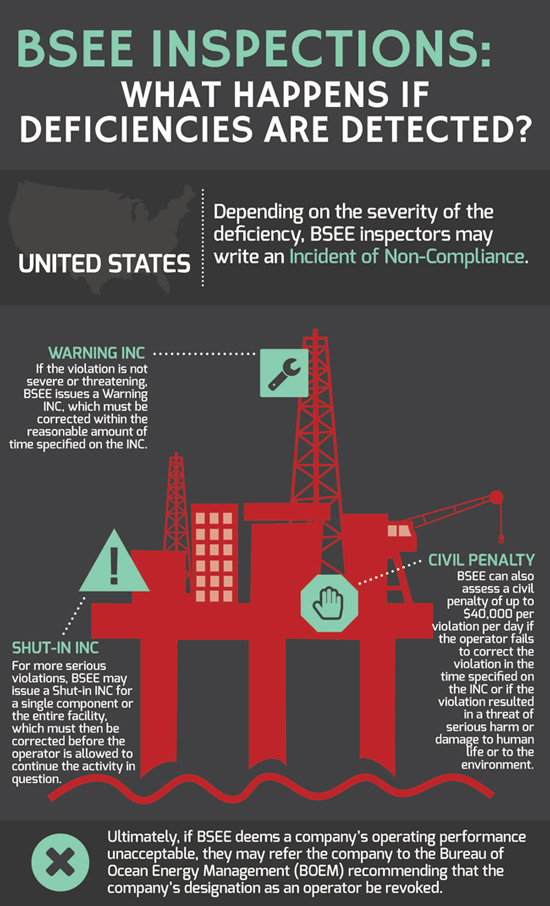

A: Most commonly, BSEE inspectors use the Potential Incident of Noncompliance (PINC) list to conduct their inspections. This is ultimately a checklist of inspection items compiled from all regulations and guidelines for safety and environmental requirements. BSEE also uses other factors such as accidents, pollution events, civil penalties and incidents of noncompliance to evaluate the overall performance of offshore operators.