- Have any questions?

- +985-727-7400

SEMS Field Assessments Q&A

Well Control Testing Part 2 of 3: During the Test

October 29, 2015

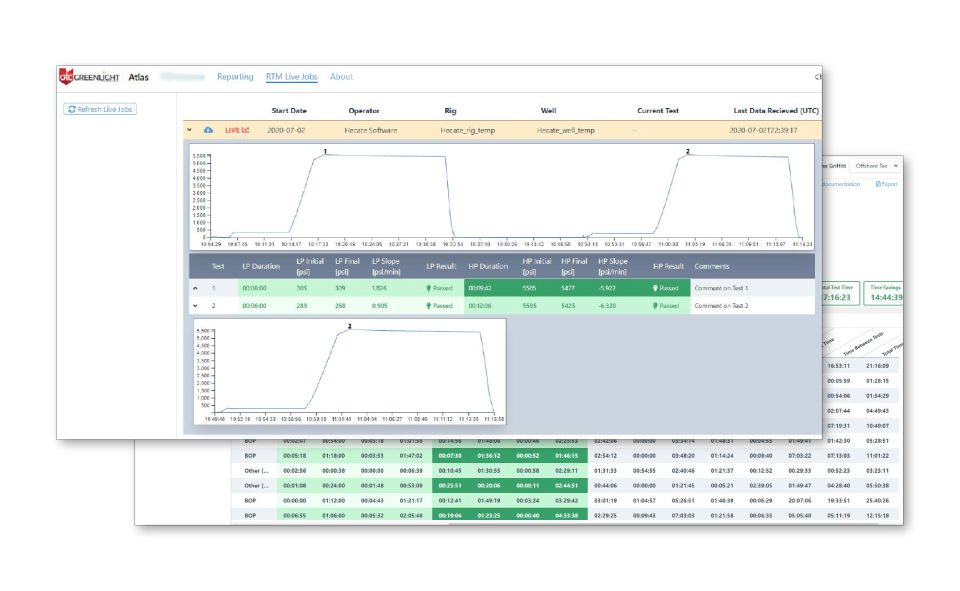

Offshore Technical Compliance and Hecate Software Introduce New Digital Pressure Testing Software

December 3, 2015

SEMS Field Assessments Q&A – 10/30/2015

At OTC, it is our goal to keep up with evolving trends and changes in the oil and gas industry so that we can continue to provide our clients with the knowledge and resources necessary to keep your organization compliant and operating safely.

Below, Perry Jennings, one of our Senior Inspectors and Safety and Environment Management System (SEMS) consultants, provides guidance for adhering to BSEE’s SEMS rule.

Q: What is SEMS?

A: The Safety and Environmental Management Systems (SEMS) program is a performance-focused tool established to enhance the safety and environmental protection of offshore oil and gas drilling operations by reducing the frequency and severity of accidents. The SEMS program is regulated by BSEE using audits to determine whether operators have developed and implemented a SEMS program and to set a baseline for measuring progress.

Q: What is the purpose of a SEMS Field Assessment?

A: A SEMS Field Assessment is conducted to ensure all SEMS objectives outlined by BSEE are actively being met. Operators should aim to conduct a SEMS Field Assessment no later than 90 days prior to the official audit date; however, if possible, OTC recommends conducting a field assessment immediately after determining the date of an upcoming SEMS audit and the asset to be audited. This will allow time for implementing corrective action for any gaps identified during the assessment.

Q: Who conducts SEMS Field Assessments?

A: OTC is equipped with a team of trained inspectors, many of which previously worked as MMS/BSEE/USCG inspectors. Their intimate knowledge of SEMS regulations and auditing procedures, combined with years of firsthand experience and expertise of domestic and international regulations, allows them to conduct thorough and comprehensive assessments.

Q: What can operators expect during a SEMS assessment?

A: The assessment is directly aligned with the auditing procedures used by BSEE and COS accredited auditors. The assessment team conducts a thorough evaluation of all offshore operations, bridging documents, hazards analysis, P&ID’s, MOC and personnel awareness to determine their knowledge and application of the SEMS regulations.

OTC inspectors begin the assessment by collecting relevant documents from both the operator and the contractors to gauge the program in place and proceed with a thorough evaluation of the foundational documents provided based on the SEMS requirements. Based on the gathered documentation, the assessment team becomes familiar with what should be in place offshore and develops specific areas of focus for the field assessment. The SEMS field assessment process includes offshore documentation review, interviews with offshore leadership and personnel and a final report of findings that is delivered following the field assessment.

Q: What tools are used for SEMS Field Assessments?

A: OTC inspectors use a strategically formulated questionnaire to gauge the operator’s compliance and personnel’s knowledge of the SEMS program in place.

Q: How long does the entire assessment process take?

A: This process typically takes between 5 to 10 working days per facility including onshore preparation, documentation review and offshore assessment depending on the size and complexity of the SEMS plan and facility operation.

Q: What is included in each portion of the assessment, and how are the assessment results delivered?

A: The OTC assessment team hosts an oral consultation to discuss findings with the operator’s field management and delivers a field assessment report directly to the offshore installation manager prior to leaving the facility. This report details each evaluation performed by the assessment team, including personnel interviews and reviews of past records to identify any discrepancies in the SEMS program. OTC then compiles a formal, comprehensive report of findings and recommendations that is delivered to the operator’s executive management team.

Q: Where can operators learn more about SEMS requirements?

A: Operators, contractors and field personnel can visit the BSEE website to learn more information about the SEMS program and its objectives.

Q: How can operators and contractors better prepare for SEMS assessments?

A: Operators were required to implement a SEMS program by Nov. 15, 2011, and comply with the provisions of the SEMS II Rule by June 4, 2015. Operators may choose to review the SEMS program on the BSEE website to become more familiar with the regulations in place, but other than being in compliance with all SEMS regulations during normal operations, there are no additional measures to be taken to prepare for a SEMS audit.

One of the key benefits offered by OTC to our clients is that we employ the services of former MMS/BSEE/USCG inspectors who have firsthand knowledge of SEMS regulations and actual experience with the initial development of SEMS. It is our goal at OTC to provide our clients with the best possible guidance and training to assist with your compliance and safety needs, and who better to provide this expertise than a team that has worked directly with the industry’s regulatory bureaus?