- Have any questions?

- +985-727-7400

The Right Tool for the Job

Offshore Technical Compliance Introduces New Regulatory Compliance Trainings

June 2, 2016

Marine Regulatory Compliance is a Necessity

June 2, 2016

BLUEPRINT – New Software Changing the Way Test Plans for BOP and CM Valves are Created

Every successful job starts with a solid plan to provide a map for how a project will flow, and testing BOP and CM valves is no different. Based on more than a decade of experience in pressure testing and inspection services, Offshore Technical Compliance and Hecate Software, Inc. have jointly created BLUEPRINT, a software tool for designing test plans for BOP and CM valves for the oil and gas industry.

“We’ve found that several of our clients struggle to create their testing plans using Microsoft Excel, Paint, Visio or other general office software tools that aren’t specifically designed for creating test plans for BOP’s and CM’s,” said Mike Bethea, CEO of Offshore Technical Compliance.

BLUEPRINT is a palette-driven drawing program that is specifically designed for testing BOP and CM components. Although there are a few players in this market offering test plan tools, BLUEPRINT is capturing attention due to its ease-of-use for clients and its effectiveness in creating testing plans.

Pressure testing involves three main phases:

- Planning for the tests,

- Performing the tests; and

- Reporting on the tests.

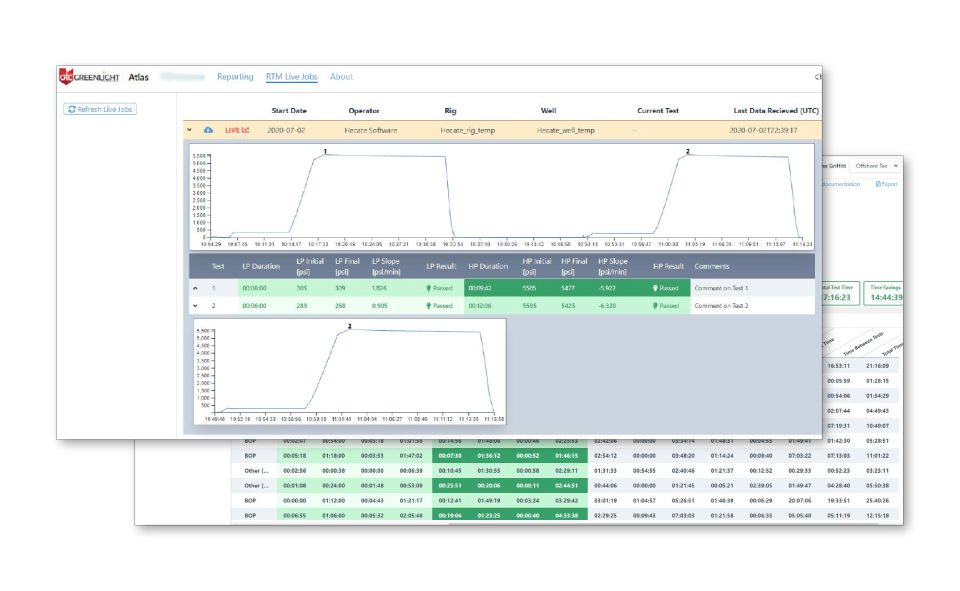

OTC GREENLIGHT allows users to perform the tests, and LEAFLET handles reporting on the tests; with the addition of BLUEPRINT as the third component, planning for the tests is now covered, too.

BLUEPRINT works seamlessly with other tools in the OTC GREENLIGHT suite of software to provide a complete digital pressure testing suite that can be used to conduct, analyze and document a wide variety of pressure tests, including BOP’s.

“Whether used as a stand-alone testing design tool or as part of the complete digital pressure testing software suite, BLUEPRINT is another resource to ensure oil and gas companies have the right tools to ensure success and safety,” said Eric Livesay, CEO of Hecate.

Once the software is installed, the user is able to design test plans from their own computer while ensuring the validity of their plans using the software suite. Several operators currently create images of their test plans using general office software packages which do not have a method to test the validity of plans.

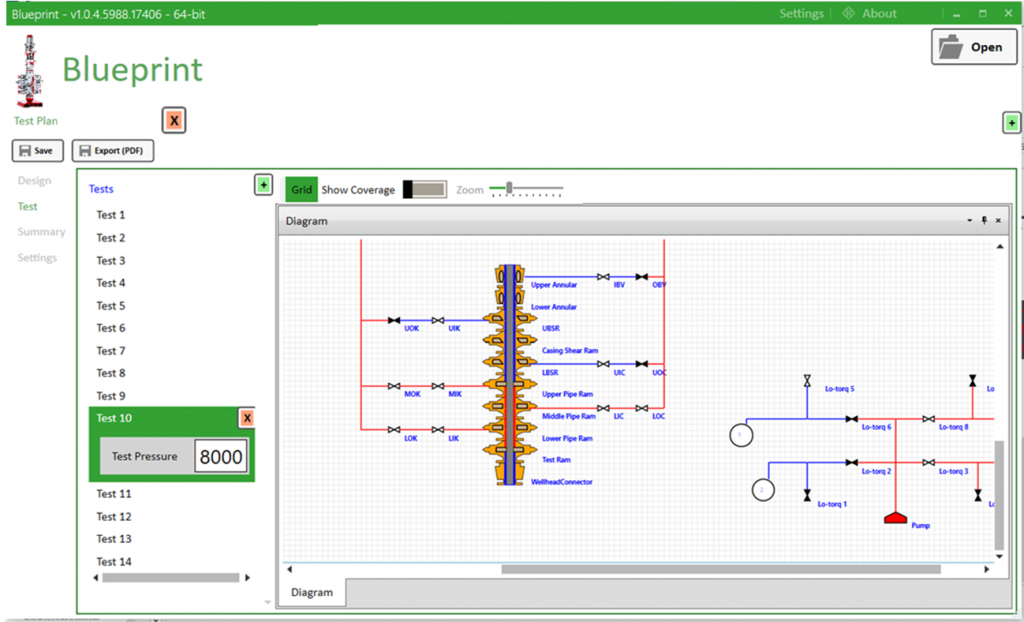

BLUEPRINT will be able to check the validity of tests including telling the user if all valves that need to be tested have been tested and ensuring all valves being tested have a valid bleed-path. A custom test validation algorithm being integrated into BLUEPRINT will also alert the user to trapped pressure.

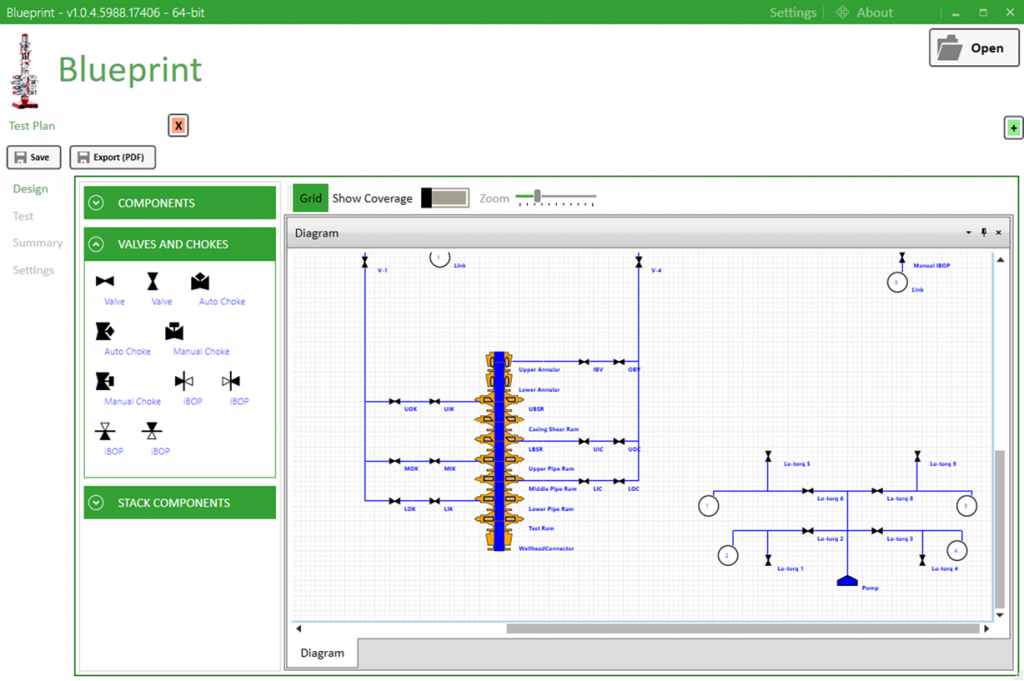

The design software interface features a palette of BOP and CM valve components, zoom feature and a drawing area with a snap-to-grid feature. The user can define any number of tests, each with an independent test pressure. BLUEPRINT automatically traces pressure throughout the BOP and CM for each test.

BLUEPRINT allows users to design a choke manifold and a BOP stack including ram and annular components. A user can design numerous tests to factor in multiple variables including turning on a pressure source and setting the state of the components incorporated into the design. BLUEPRINT includes summary capabilities to generate a table that illustrates the valves that have been tested and can also output an easy-to-share PDF document that includes one test per page.

OTC GREENLIGHT operators have been using BLUEPRINT in the field with much success, and as more permanent installations of the OTC GREENLIGHT system are installed on job locations, rig personnel will be using BLUEPRINT themselves as part of the OTC GREENLIGHT suite of pressure testing tools.

BLUEPRINT has proven to be an accurate tool for oil and gas BOP and CM valve pressure testing planning to meet higher compliance demands while offering time savings that directly impact overall costs of operation.

The image above shows the design page of BLUEPRINT. Components can be dragged from the palettes on the left side of the window and dropped onto the drawing area. The user can toggle the display of a grid that is used for positioning the components and zoom in and out on the image.

The image above shows a test in BLUEPRINT. The red lines show locations in the choke manifold and BOP that are under pressure. Blue lines indicate locations that are not under pressure.