- Have any questions?

- +985-727-7400

BLUEPRINT Reaches Into New Area

Drilling Compliance Training Makes Stop in Houston

July 14, 2017

Federal Failure Reporting an Added Step for Offshore Operations

August 11, 2017

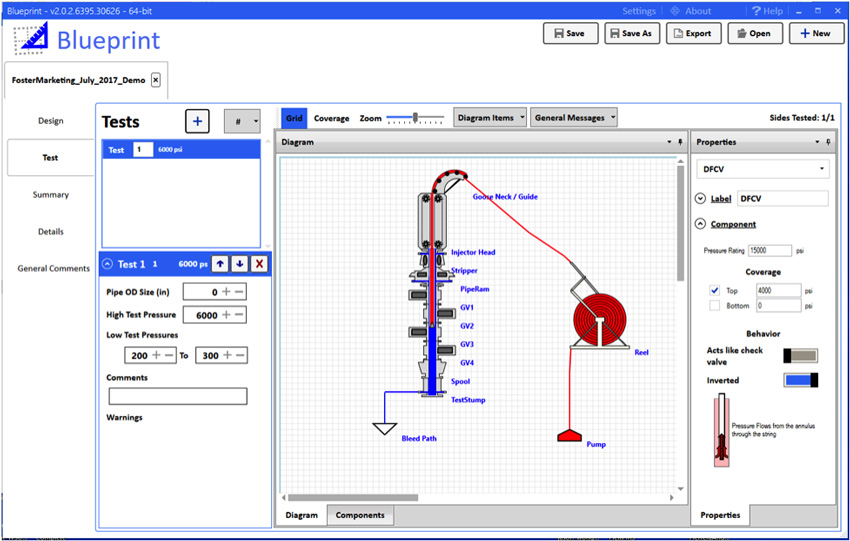

Coiled Tubing Stack Capabilities Added to Palette-driven Drawing Program’s Offerings

BLUEPRINT – a palette-driven drawing program specifically designed for creating testing plans for BOP and CM components – is stacking up the reasons for customers to turn away for using general office and other software tools to create test plans.

BLUEPRINT, a joint effort by Offshore Technical Compliance and Hecate Software Inc., has captured much attention in the oil and gas industry for its ease-of-use and effectiveness in creating testing plans. Now in version 2.0.2, the recently released BLUEPRINT update offers significantly expanded capabilities for describing a coiled tubing stack.

“As with all our software efforts, we are thrilled when we see these tools changing how oil and gas companies work to create more efficient and safer operations,” said Mike Bethea, CEO of Offshore Technical Compliance. “But, we never stop there. We are committed to creating and supporting smarter solutions in the industry to ultimately help our clients achieve their operational goals.”

One of the new major additions BLUEPRINT users will see is an expanded palette for coiled tubing components. Although previous versions of BLUEPRINT did have a coiled tubing component palette, the latest version has been significantly expanded.

The new coiled tubing component palette includes entries for:

- Two gate valve orientations;

- A realistic coiled tubing reel that can be shown in two orientations;

- An injector head and stripper;

- A goose neck/guide that can be shown in two orientations; and

- Rams including blind, pipe, variable bore and shear options.

“The palette entries for a coiled tubing stack are physically smaller than those for a BOP stack for more accurate test planning,” said Eric Livesay, CEO of Hecate.

Additionally, BLUEPRINT now allows tubing inside of the stack to be blocked in three ways – plug, check valve or check valve – inverted.

In the plug scenario, flow is restricted down the tubing as well as up the tubing. If check valve blocking is applied, the flow is restricted to only one direction with flow being allowed down the tubing but not up the tubing. If the check valve – inverted option is used, flow will be restricted in only one direction, allowing flow up the tubing but not down.

BLUEPRINT’s coverage algorithms have been updated to accommodate either plug or check valve scenarios inside the tubing, with entries displayed on the summary table as well as in printable PDF reports generated via the software.

“To illustrate BLUEPRINT’s expanded capabilities, clients can now create testing plans that include an inverted dual flapper check valve inside of the stack – both orientations of the gate valve, and reel, goose neck, injector head and stripper components,” Livesay said.

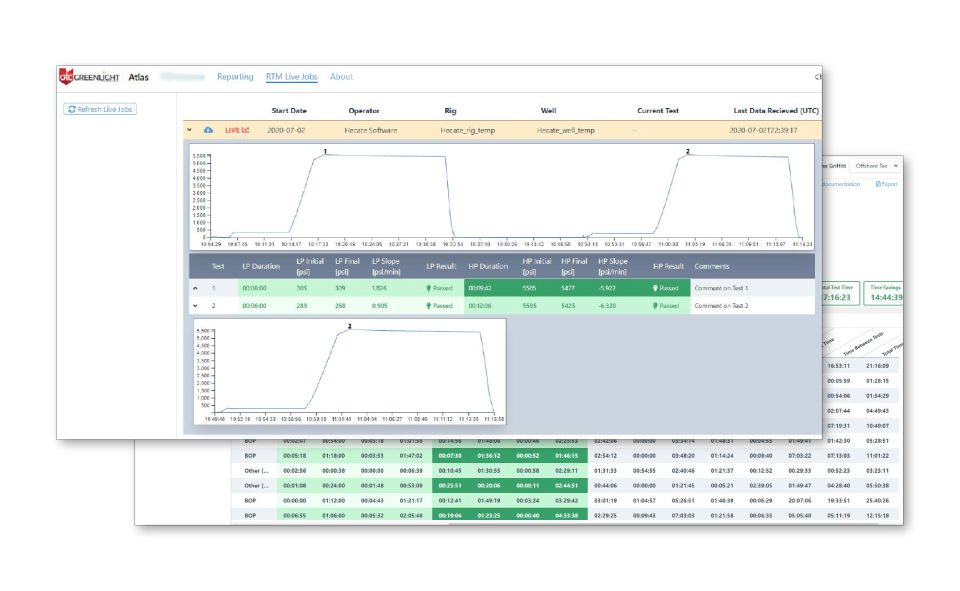

BLUEPRINT is one of the essential pieces in OTC’s GREENLIGHT digital pressure testing software suite. But, even if you only use BLUEPRINT as a stand-alone testing design tool, it’s time to take another look at what more you can now do with this software.